26 March, 2025

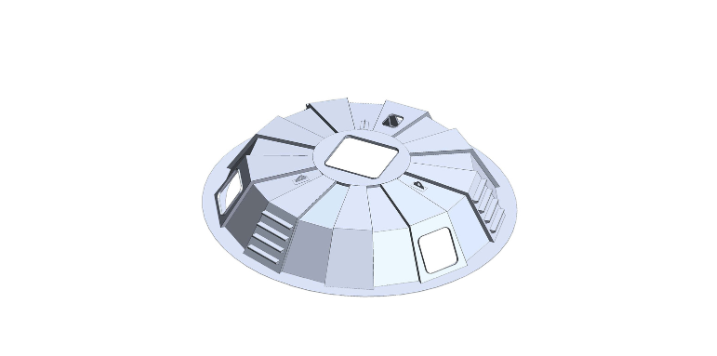

26 March, 2025Alusín Tecnología, recently welcomed as a member of AFMEC, has successfully completed the design, manufacturing, and delivery of its first TP Cover for the offshore wind energy sector. This self-supporting structure, over 8 meters in diameter and made entirely of aluminum, is designed to operate under demanding maritime conditions.

The project posed significant technical challenges, requiring compliance with strict industry standards, including welding procedure qualification according to DNV standards and sealing performance certification under UNE-EN 60529. Alusín was responsible not only for the production but also for the full design and technical conception of the cover.

This delivery expands Alusín Tecnología’s portfolio of components for the offshore wind sector, which already includes railings, doors, platforms, and internal structural elements. The company applies advanced welding techniques—including MIG, TIG, and Friction Stir Welding (FSW)—to tackle both light and heavy aluminum fabrication with a high level of precision and quality.

ALUSÍN TECNOLOGÍA has more than 30 years of experience in Aluminum Welding and Boilermaking, with the capability to manage any project, from light to heavy parts. Certificates: EN 3834 and 1090, ISO 9001. MIG/TIG Welding, and Friction Stir Welding (FSW).

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.