24 November, 2021

24 November, 2021Goimek, Danobatgroup´s high precision machining and large machining company, recently invested 2.2 million euros in the acquisition of a state-of-the-art gantry milling machine with moving table from the machine tool manufacturer Soraluce, of the same industrial group.

With the purchase of the new SORALUCE PM 10000, Goimek extends its capabilities in precision milling and achieves a greater degree of flexibility in its value proposition to meet the needs for manufacturing of parts for strategic industrial sectors such as power generation and capital goods.

Apart from the machine, the investment included adapting the production facilities of the Basque company to ensure the stability and precision of the machine, as well as the purchase of tools and fixtures and professional training to be able to design optimal machining processes.

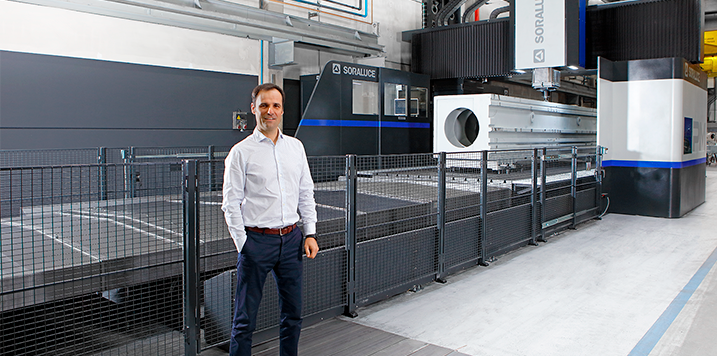

“This investment is part of our commitment to put us at the technological forefront and our efforts to strengthen intercooperation with other companies in order to further step up our capabilities, diversify our business area and offer our customers high value-added solutions,” says Aitor Alkorta, General Manager of Goimek.

“We now have several Soraluce solutions and we are therefore very familiar with their capabilities and their advances in the area of digitisation, which fit perfectly with our innovation strategy. We have put our trust in Soraluce once again for its ability to develop high-performance machines along with technological applications incorporated on the machine, enabling us to move toward operational excellence, a key factor for a machining company like Goimek,” notes Aitor Alkorta.

This operation is embedded in the strategic plan of the Itziar-based company, which has included other major investments in recent years such as the purchase of a 16-meter multi-function floor type milling machine and a new three-dimensional solution from Zeiss, among other equipment.

For the company´s next strategic plan, which will run until 2024, Goimek is expected to carry out new investment projects in machines, verification means, production facilities as well as transformation projects.

A solution at the cutting edge of technology

The SORALUCE PM 10000 acquired by Goimek is a portal milling machine with a load capacity of 40,000 kg on the table. The high-capacity solution has a longitudinal traverse of 10,000 mm, a cross ram traverse of 5,000 mm and a vertical ram traverse of 1,600 mm. The distance between columns is 4,210 mm and the distance from the table to the gantry is 2,366 mm. The table working area, configured to achieve high accuracies, is 9,300 x 3,000 mm.

The machine has a complete cast-iron structure, ensuring the accuracy and rigidity requirements demanded by the machining company. The cast parts of the machine also ensure long-term stability and thermostability of the entire assembly, keeping expansion under control and dampening vibrations, a feature that guarantees excellent performance in varying temperature conditions.

The new milling machine has linear guiding on all its axes, which guarantees high levels of precision and dynamics. With a robust design with 4 guides on the longitudinal axis, the resulting configuration ensures minimal deformation of the workpiece.

In addition, the hydrostatic anti-vibration runner blocks enable passive damping and thus provide the required stability during the machining process.

Both the cross and longitudinal axes of the machine include a double pinion and rack drive systems with electrical preload, a technology that ensures long-term accuracy and is resistant to mechanical wear, as compensation is carried out electronically.

The machine incorporates several heads with high stock removal and finishing capabilities for precision parts. In this respect, it allows surface grinding and specific facing and diamond dressing cycles.

In addition, the solution incorporates the DAS® Active Damping System, a Soraluce development to suppress chatter and ensure consistent machining throughout the process. It also has an adaptive control of the machine tool manufacturer, which automatically adjusts the cutting parameters to the actual machining conditions, and the Accura Heads technology device, which compensates for any deviation in the positioning caused by the head articulations. Furthermore, it features the Soraluce VSET measurement system, based on 3D vision technologies to reduce time-consuming set-up processes and raw-part alignments.

The machine has the latest digitisation innovations from Soraluce such as the Smart HMI system, along with the latest version of the Heidenhain TCN 640 control unit, a smart and user-friendly interface that allows you to run the numerical control program in the work area and connect other applications that offer various functionalities such as monitoring the energy consumption.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.