25 March, 2025

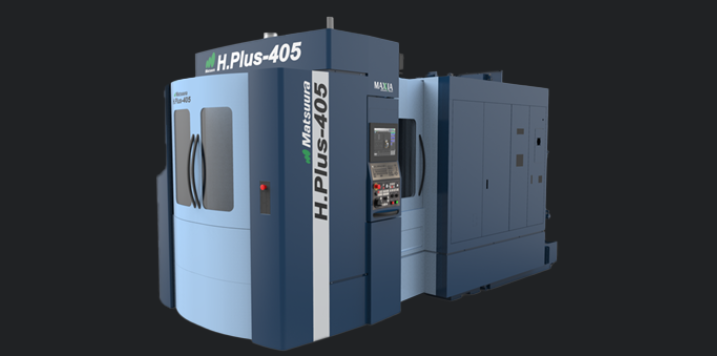

25 March, 2025The Gipuzkoan company Mecapal has recently acquired a Matsuura H.Plus-405 horizontal machining center from Maquinser. This acquisition supports its strategy to boost production capacity and meet the precision and flexibility requirements of the automotive industry.

The new machine is designed for large-part machining, with extended X/Y/Z axis travels up to 660 mm. It stands out in its category for handling the largest part sizes while reducing floor space usage by 12% and improving operational accessibility.

Key features include rapid traverses of 60 m/min, a direct-drive B-axis capable of 100 rpm, and a drum-type tool changer with 60 positions and a 1.2-second tool change time. These specifications contribute to significantly reduced downtime and increased productivity.

MECAPAL is a family business dedicated to precision machining by CNC for the most demanding industrial sectors, such as automotive, railway, hydraulics and auxiliary components, additionally providing them with the possibility of designing and manufacturing the most complex and efficient tools for the own manufacture. With an area of more than 3,000 m², MECAPAL has the latest generation of C.N.C. with a capacity of 25 - 1000, Tornos C.N.C. Ø30 - Ø260 as well as various specific machinery (robotic transfer with 100% verification,….).

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.