24 February, 2025

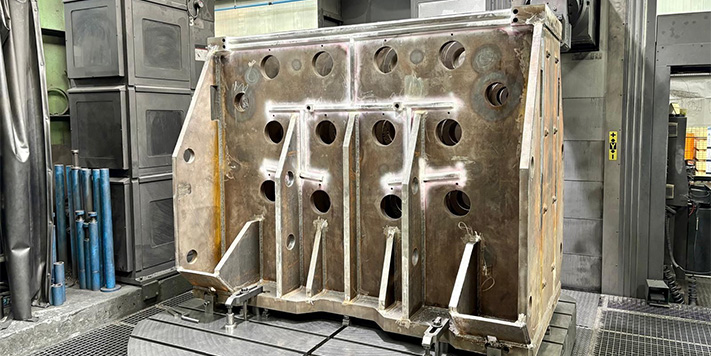

24 February, 2025MEKALERUN has taken another step in optimizing its machining processes by incorporating a Minimal Quantity Lubrication (MQL) system into its LAGUN GMP 5 boring machine. This technology significantly reduces lubricant consumption, minimizing environmental impact and improving production efficiency.

MQL is a technique that optimizes lubrication and cooling during cutting by using a minimal amount of fluid. Its main benefits include:

MEKALERUN is a company with over 30 years of experience in precision machining, specializing in finishing boring, milling, and grinding processes. It offers services for medium and large-sized parts, handling up to 60 tons and 20 meters in length, including the possibility of delivering painted parts from its own facilities. The company has a team of 30 professionals and more than 2,700 square meters of facilities in Elgoibar, Gipuzkoa. Its main customers belong to the machine tool and capital goods sectors.

MEKALERUN is part of MAHER HOLDING, alongside LAGUN MACHINE TOOLS, allowing it access to state-of-the-art machinery. With this update, the company reaffirms its commitment to innovation and sustainability in the advanced manufacturing sector, optimizing its processes without compromising the precision and reliability that define its production.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.