04 October, 2024

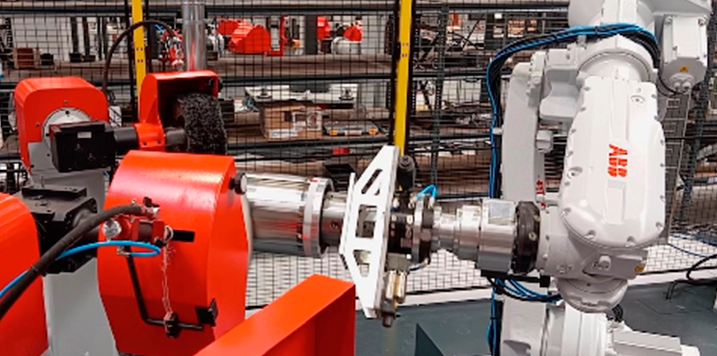

04 October, 2024Ruymor, a leading company in the metal forming sector and specialising in the manufacture and assembly of electromechanical solutions, has incorporated a state-of-the-art robotic cell for sanding and polishing stainless steel and aluminium parts into its facilities. This acquisition represents a significant advancement for the company in terms of improving the surface finishes of its products, a key aspect in highly demanding sectors.

The new robotic cell is designed to achieve roughness levels as low as 0.05 microns, a critical parameter for ensuring the highest quality and reliability of the produced parts. This cutting-edge technology is particularly relevant in industries such as food, medical, nuclear, and chemical, where precision and flawless finishes are essential to comply with strict regulations and quality standards.

In addition to improving precision in the sanding and polishing processes, this robotic cell increases production capacity, positioning Ruymor to meet growing demand in these critical sectors. The automation of the process not only reduces production times but also minimises the risk of human error, ensuring superior consistency in the finishes.

This strategic move reflects Ruymor's strong commitment to innovation and the continuous pursuit of excellence in its production processes. By investing in state-of-the-art technology, the company ensures its ability to offer competitive products, staying at the forefront of an increasingly demanding market.

Ruymor’s decision to invest in this new technology underscores its intent to continue leading in its sector, providing electromechanical solutions that meet the highest standards of quality and reliability, tailored to the specific needs of clients in highly regulated sectors. With this new robotic cell, the company strengthens its ability to continue offering high value-added products.

04 October, 2024Ruymor, a leading company in the metal forming sector and specialising in the manufacture and assembly of electromechanical solutions, has incorporated a state-of-the-art robotic cell for sanding and polishing stainless steel and aluminium parts into its facilities. This acquisition represents a significant advancement for the company in terms of improving the surface finishes of its products, a key aspect in highly demanding sectors.

04 October, 2024Ruymor, a leading company in the metal forming sector and specialising in the manufacture and assembly of electromechanical solutions, has incorporated a state-of-the-art robotic cell for sanding and polishing stainless steel and aluminium parts into its facilities. This acquisition represents a significant advancement for the company in terms of improving the surface finishes of its products, a key aspect in highly demanding sectors.